ETON Semiconductor IGBT Mounter YT10B is equipped with gantry dual-drive linear motor, which gives this model a powerful power “heart”. At the same time, the model is also equipped with modern devices such as automatic wafer disc feeder, automatic switching nozzle structure, 3-channel alcohol spraying mechanism, automatic thimble nozzle mechanism, wafer disc automatic film expansion mechanism, etc., to meet the automated production needs of customer enterprises more efficiently.

This product has been rated as the leading product of China’s semiconductor IGBT placement machine by the industry. Compared with expensive other brand products, the performance of this model is not inferior, but the cost performance is significantly higher, becoming the preferred product for Chinese semiconductor placement machines.

It is used for automatic loading and placement of wafers, solder lugs, spacers, stacked product materials and tooling materials in IGBT packaging. The equipment platform, modular hardware design and software modular architecture can flexibly match equipment functions based on the needs of the production line process, and the equipment is suitable for industrial modules, vehicle modules and other situations that require placement processes.

Semiconductor IGBT Mounter YT10B Features:

- It can mount multi-form materials: chip mounting (wafer 6 inches, 8 inches or 12 inches, or tray loading), solder patch (tray loading/feeder/vibrating plate loading), Spacer mounting, stacking DBC, etc

- Modular design, flexible configuration: equipment platform, modular hardware design and software modular architecture

- The software interface is flexible and user-friendly, and the programming is guided

- High accuracy of the sticker: radial ±5U, rotation ±0.05°, Sticker force control ≤70g, Sticker laser measurement accuracy ±10U

- Ejector pin heating and module quick change: The thimble has heating function (temperature can be set) to increase the speed of tearing film, and the thimble sleeve is automatically replaced

- Strong information tracking function: wafer mapping information reading, ink dot automatic identification, 1D code automatic reading, material placement position tracking

- Support common communication protocol: provide Secs-Gem manual and SVID information

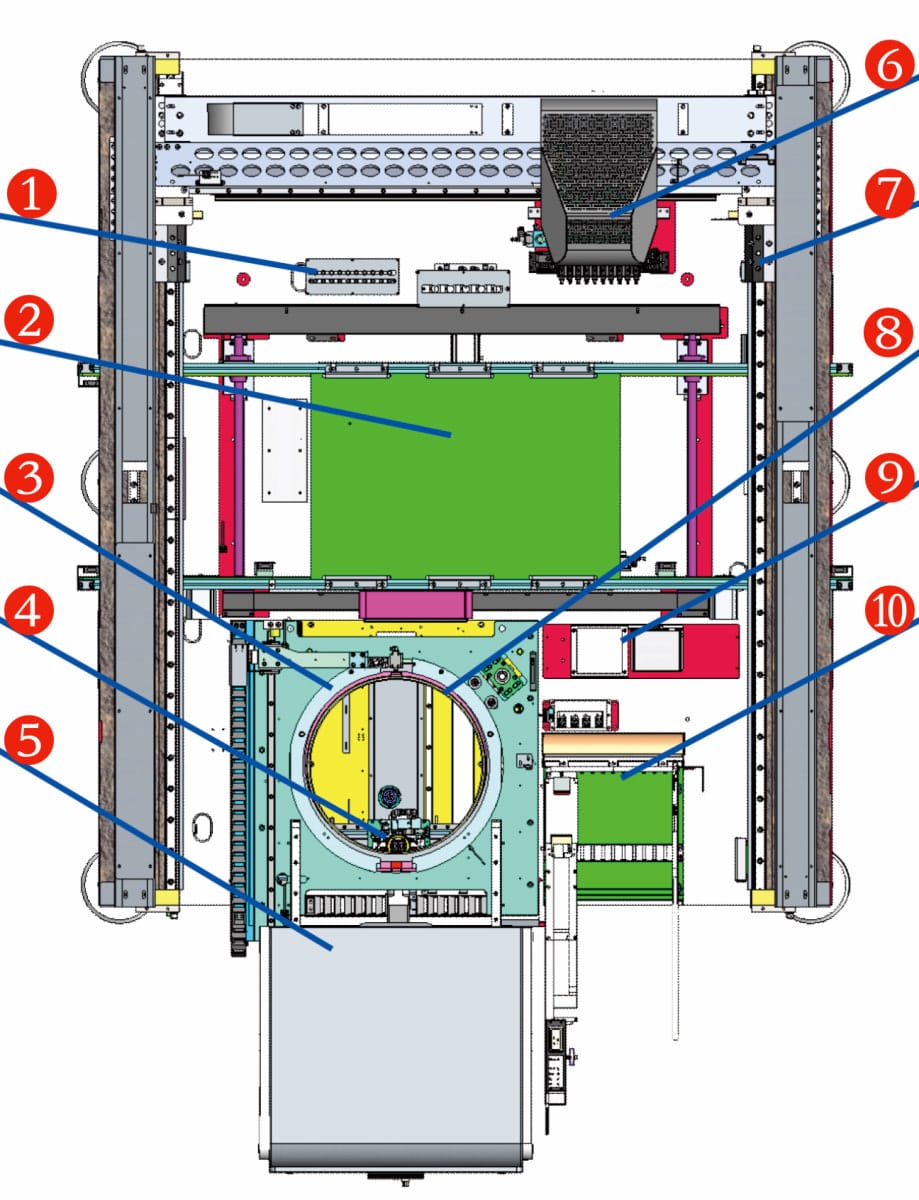

Semiconductor IGBT mounter YT10B internal structure display:

❶: Automatic switching of nozzle device

❷: Automatic widening of the transport track

❸: Wafer disc automatic expansion mechanism

❹: Automatic thimble replacement mechanism

❺: Automatic wafer tray loader

❻: 10 nozzle placement head

❼: Gantry dual-drive linear motor

❽: 3-channel alcohol spraying mechanism

❾: Bottom flying camera

❿: 4 stations to fly to the platform

Technical parameters of semiconductor IGBT placement machine YT10B

| Model | YT10B semiconductor mounter machine |

| Dimension | |

| L*W*H | L 2200 X W1480 X H 1520mm |

| Total weight | 2110kg |

| PCB | |

| PCB size(L*W) | Max size: 600mm*400mm Min size: 50mm*50mm |

| PCB thickness | 0.5-18mm |

| PCB clamping | cylinder clamping, track width adjustable |

| Rail | Single-track, single-arm |

| o.s. | |

| System | Windows 7 |

| software | ETON R&D independently |

| Production Management MES option | Customized(Option) |

| off-line programming | Optional disposition |

| Vision system | |

No. of camera | 1 set/bottom fixed flying racket(Digital camera) |

| Vision alignment+Mark correction | |

| Repeat precision | ±0.01mm |

| Mounting speed | 1.5K UPH |

| Mounting height | ≤20mm |

| Components | 0.1 *0.2~16*16mm |

| Power | 380AC SOHZ |

| Power consumption | 1.2KW |

| Operating environment | 23°C±3°C |

| Transmission direction | Standard: Single direction |

| Transmission mode | Online drive |

| Position mode | Optical |

| Air consumption | 0.4-0.6mpa (4-6kgf/cm2) 200L/min |

| Electrical control | Independent research and development by ETON |

| Motioncontrol card module 1 set | Independent research and development by ETON |

| X,Y,Z Axis drive way | High-end magnetic linear motor |

| Number of nozzles | 10PCS |

| Feeding/feeding system | |

| Adhesive spraying feeder: | Plug and play, size L444 W100H115MM nozzle configuration: 1 vertical nozzle, 2 cross nozzles (32°C), support special customization |

| Solder lug feeder | Size: L623W81H113.5MM corresponding solder lug: W2-20mm, L2-17mm, support special customization |

| Feeder | NTC electric feeder |

| Flux dipper | Size: L444W230H115MM can be dipped in solder paste/flux, adjustable thickness 50um~3mm |

| Wafer feeding system | Support 6-inch, 8-inch, 12-inch wafers (10 layers), chip thickness 50um |