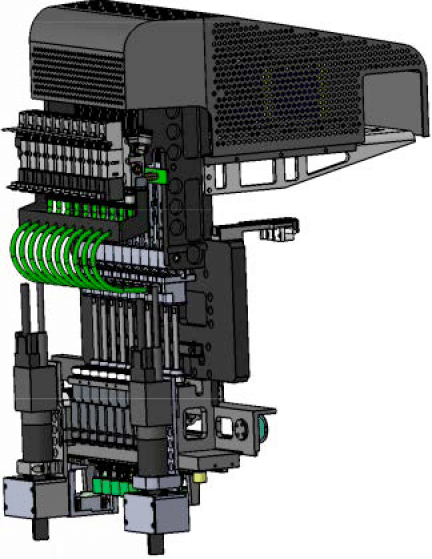

LED high-speed ETON mounter F7S for display screen Features:

Aliquam lobortis nec er

Optimal production capacity

180000CPH

| Length | 2700mm |

| Width | 2300mm |

| Height | 1600mm |

| Total weight | 1700kg |

diverse functions,efficient production

Feature : HIGH PRODUCTIVITY

ETON R&D Adjustable Placement Head

Component picking position can be adjusted according to PCB pad pitch,min 13mm. Apply to LED 3014/3020/2835/5050 resistor,capacitor, bridge rectifier etc.wide componentrange.

Unique Design Component Leaking Detection And Individual Component Refill Function

Recognition camera record the component leaking position of PCB, independent Angle and mounting can be achieved by a separate feeder

Ultra-high-speed Capacity

The mounting head adopts group taking and group placing, which is greatly shortened by improving the process of taking and placing time, to achieve the company’s optimal conditions under 180000CPH excellent mounting ability.

Technical parameters of ETON machine F7S:

| Model | HT-F7S [formerly HF-F8] |

|---|---|

| PCB Length width | Max:1200*330mm min:100*100mm |

| PCB Thickness | 0.5~5mm |

| PCB Clamping | Adjustable pressure pneumatic |

| Mounting mode | Group to take and group to mount |

| System | Windows 7 |

| Software | ETON R&D Independently |

| Display | LED monitor |

| Input device | Keyboard,mouse |

| No.of camera | 5 PCS (Digital camera) |

| Vision alignment,Mark correction | |

| Repeat mounting precision | ±0.02mm (Repeat precision) |

| Mounting height | ≤5mm |

| Mounting speed | 150000~180000 CPH |

| Components | LED 3014/3020/3528/5050 and resistor,capacitors,bridge rectifiers |

| Components space | 0.5mm |

| No. of feeders station | 68 PCS |

| No.of head | 34 PCS |

| Power | 380AC 50Hz |

| Power consumption | 6KW |

| Operating environment | 23°C ± 3°C |

| Conveyor transmission | Max Length:1200 mm |

| Transmission speed | >500mm/sec |

| Transmission direction | Single(left➔right or right➔left) |

| Transmission mode | Online drive |

| Positioning way | Optical |

| Air supply | 0.4-0.6mpa(4-6 kgf/cm2)150N/min |

| Electrical control | Independent research and development by ETON |

| Motion control card module 1 set | Independent research and development by ETON |

| X,Y Axis drive way | High-end magnetic linear motor+servo motor |

| Feeding way | electric feeder with double motor |

| Mixture detection and automatic feeding function | Standard configuration |